Samarkand paper production

Paper production secret was known as early as from the ancientry. The Chinese were the first to begin paper production, thereat its know-how was kept in a strict secret till the VIII century. According to history when Chinese troops intruded to the territory of the Samarkand ruler Abu Muslim in the mid-VIII century the Samarkand forces offered fierce resistance to the invaders and defeated the outlanders. In the course of the battle a lot of captive Chinese were captured and among them there were masters in paper production. They agreed to disclose the secret and set up paper production in Samarkand in exchange of their life. From this moment till the XVIII century Samarkand became a Central Asian center for silk paper production.

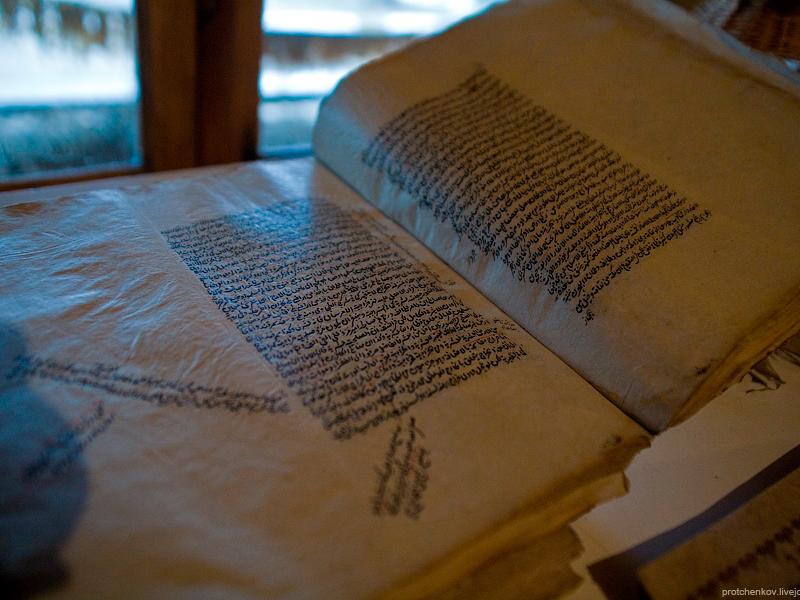

The Samarkand paper was in great demand due to its smoothness and color, but its main quality was the durability. The majority of documents written on the Samarkand paper preserved in good state up to date and are still kept in different museums of the world. It was this paper which was used by calligraphists for the texts and artists for the miniatures. The Samarkand paper was also preferred in book production.

The Samarkand paper was very expensive and was produced in different grades. The“Sultan” paper considered the best grade eased out papyrus and leather from the European markets in early Middle Ages. The “Silk” grade rated the second which featured with its smoothness but was of light yellow color. The “worst” grade was considered “nimkanop” which was almost brown in color. This grade of paper was produced from silk wastes with an addition of admixtures.

Due to constant internal wars, which struck Central Asia in the XVI-XVIII centuries, the Samarkand masters had to leave their shops and move to more peaceful regions. Gradually by in the XIX century Samarkand paper production began recessing. It was only in the XX century owing to an initiative of UNESCO when the Samarkand paper production began its revival.

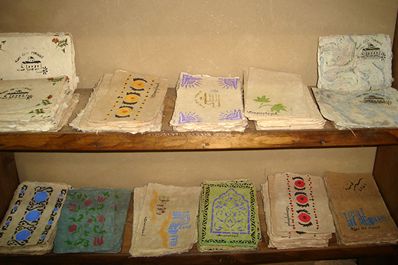

Nowadays “Meros” Paper Mill founded by Mukhtarovs brothers, well-known masters, is operating in Konigil village near Samarkand. Thanks to their efforts the ancient paper production tradition by old technologies was restored. It is an interesting fact, that the whole production is carried out manually and every Mill guest may watch the paper production process de visu

The paper production technology is as follows. Silk waste, mulberry bark and bamboo sprouts (may be replaced by wooden sticks) are used as a raw material. All these are boiled for a long period and then ground to a homogeneous mass, which are formed to thin sheets by means of a special device. Then the paper is thoroughly dried, pressed and bleached. After that the most important moment of paper production comes. The sheets are thoroughly polished on a smooth marble with the help of onyx due to which the Samarkand paper gains its famous smoothness.

Today the Samarkand paper made in Konigil Factory is widely used in ancient manuscripts, restoration work both in Uzbekistan and other countries of the world. Also, owing to production restoration, Uzbek artists can reproduce authentically old miniatures. Step by step the Samarkand paper is regaining its former fame both in Uzbekistan and abroad.

Source: http://www.advantour.com/uzbekistan/culture/handicrafts/samarkand-paper.htm